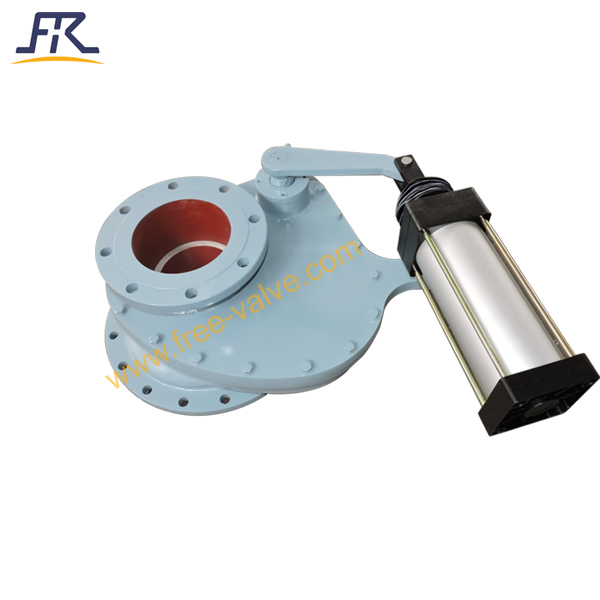

Pneumatic Tungsten carbide seat rotary disc Process Gate Valves

FREE-VALVE customized pneumatic rotary disc gate valves are designed for pressurized and vacuum systems including pneumatic conveying systems, discharge and vent applications in steel plant and coal power. The rotating disc slides across the valve body during operation, clearing out process material and cleaning the precision-lapped surface. The whole of sealing faces of the valves are well ground and polished, which is ensure a reliable sealing performance of the valve.

FREE-VALVE Pneumatic Tungsten carbide seat rotary disc Process Gate Valves are designed for pressurized and vacuum systems including pneumatic conveying systems, discharge and vent applications in steel plant and coal power. The rotating disc slides across the valve body during operation, clearing out process material and cleaning the precision-lapped surface. The whole of sealing faces of the valves are well ground and polished, which is ensure a reliable sealing performance of the valve.

Features

- The cylinder piston rod does not contact with the medium directly, which greatly prolongs the service life of the cylinder and has a higher service temperature without damaging the cylinder.

- The rotary disc gate valvedesign features a pneumatic actuator and valve that are separated allowing for easy packing without removing the valve from the pipe line on site.

- The sealing faces of the valve are made of tungsten carbide with good abrasion resistanceand prolonged service life.Tungsten carbide is sprayed on the flange ports and flow channels.

- Product with customized structural length and connection size is available.

- The valve disc rotational motion can avoid the ash deposition on the sealing surface during opening and closing, so the valves have much longer service.

- The valve body outlet end adopts slant structure, which is advantageous to the medium entering the valve cavity to fall automatically, preventing the medium in the valve cavity accumulation and causing the valve not to open properly.

- The spring between the disc and disc seat is loaded with a floating connection. The spring force of the disc always matches the valve seat, ensures the sealing of the valve, and also helps to compensate for expanding when heated and contracting when cooled ,and sealing surface wear.

- To prevent the feedback switch from being burned out by high-temperature media, the switch is not set on the valve body.

Technical Specification:

1) Size Range: NPS4~NPS12,DN50~DN300

2) Nominal Pressure: Class 150 /PN10/PN16

3) Applicable Temperature: 0~350℃

4) Connection Type: Flange

5) Sealing material: Tungsten carbide

6) Pressure test:GB/T13927, API598

7) Face to Face: GB/T12221, ASME B16.10

8) Valve body : GB/T12224,ASME B16.34

Operating Type: Pneumatic,Manual

Application:

FREE-VALVE’s Pneumatic Tungsten carbide seat rotary disc Process Gate Valves are suitable for steel plant, cereals transport system, cement transport systems and EP system in coal fired power plant. In these applications, pneumatic conveying method is used to reduce manpower demand, and improve system efficiency and reliability, and is easy to realize automation.