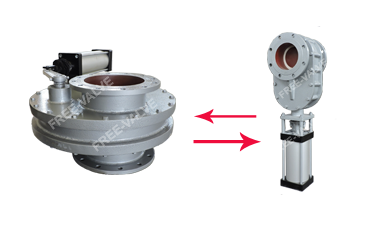

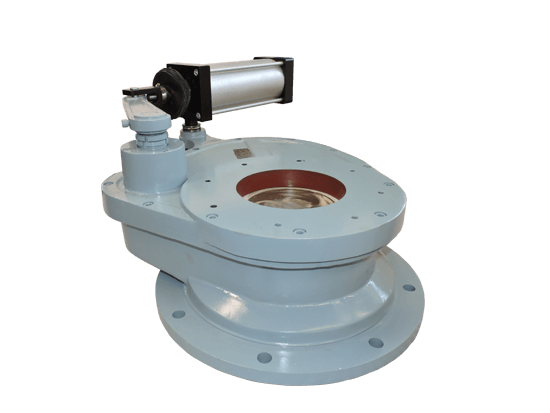

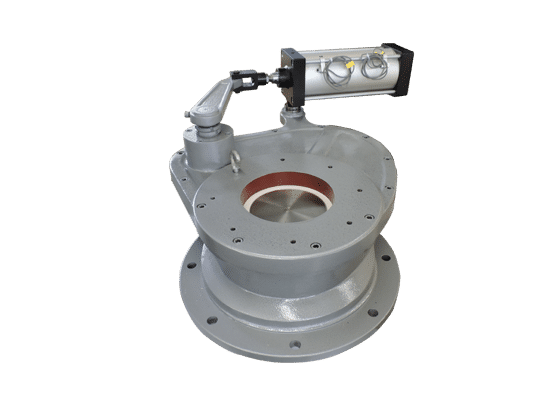

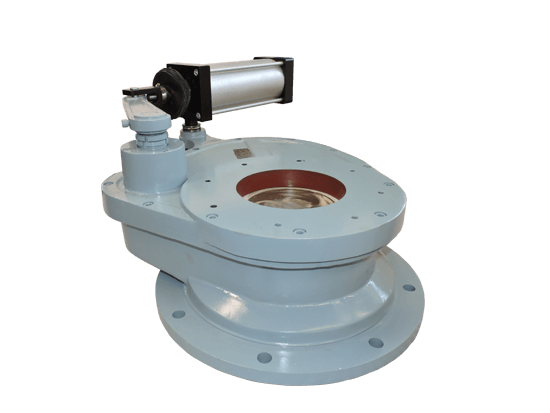

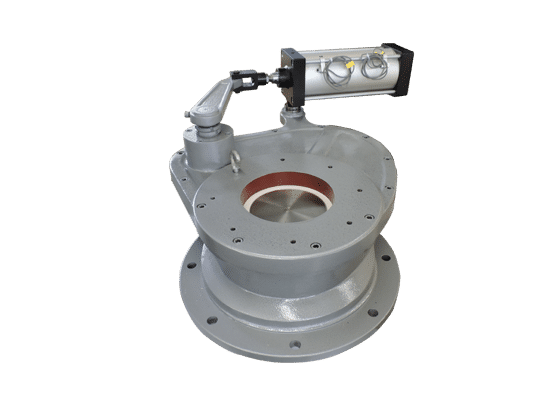

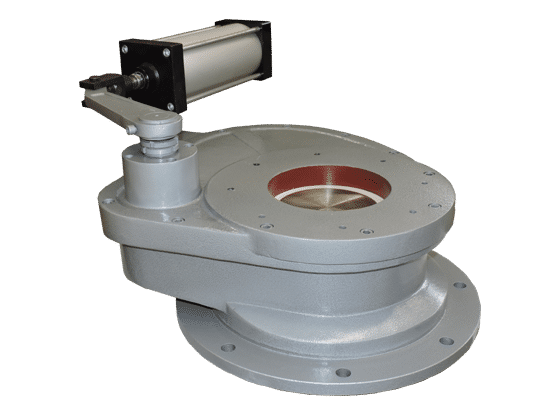

FREE-VALVE’s Pneumatic Ceramic Rotary Gate Valves are suitable for steel plant, cereals transport system, cement transport systems and EP system in coal fired power plant. In these applications, pneumatic conveying method is used to reduce manpower demand, and improve system efficiency and reliability, and is easy to realize automation.