Selection and comparison of ceramic double disc gate valves

Mar 04,2019 From: Zhengzhou Free Fluid Control Technology Co.,Ltd

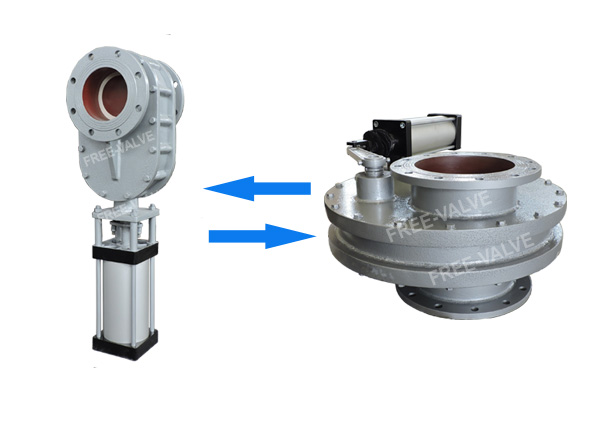

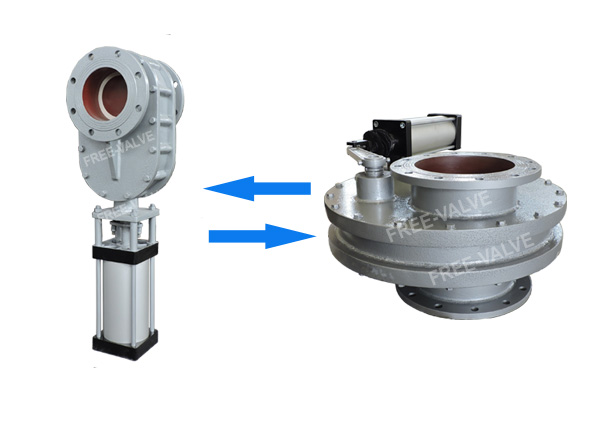

Ceramic double disc gate valve is mainly divided into straight stroke ceramic double disc gate valve and Angle stroke ceramic double disc gate valve ( ceramic rotary double disc gate valve), these two kinds of valves are widely used on pipeline of fly ash system in the coal power plant, the valve is mainly driven by pneumatic actuators, open and close quickly.

Ceramic double disc gate valve is opened and closed frequently in use (about one times/10 min) , If the packing material selection is inappropriate, the packing of straight stroke ceramic double disc gate valve is more prone to leakage phenomenon.The working medium of fly ash system is mainly dry coal dust with small particle size. Because coal dust particles occasionally adhere to the surface of the stem, when the valve is opened and closed, coal dust particles are often brought into the packing place by the stem, leading to packing wear and leakage.On the contrary,ceramic rotary double disc gate valves in the opening and closing, the stem rotates at a partial Angle, which avoids packing wear and leakage due to the stem moves up and down with media into the packing

Common features:

1.Two-side sealing can realized due to double disc structure of the pneumatic ceramic double disc gate valve.

2.It inserts spring between double valve discs to ensure self- sealing through bi-directional flexible preload pressure of spring, having characteristics of low pressure bi-directional sealing and without dust clogging phenomenon in the process of the opening and closing of valve.

3.The valve disc rotational motion can avoid the ash deposition on the sealing surface during opening and closing, so the valves have much longer service.

Different characteristics

1. Straight stroke valve packing is easy to leak.

2. Packing material selection: the Angle stroke has a wide selection of packing materials, including graphite and PTFE.but the straight stroke chooses the graphite packing is not suitable.

3. Installation space: straight stroke ceramic double gate valve requires a large installation space.

4. Weight and price: angular stroke ceramic double gate valve is heavier than the straight stroke ceramic double gate valve, the price is higher than the straight stroke.

Conclusion:

1. For valves with strict cost and weight control, straight stroke ceramic double gate valves are preferred.

2. For the straight stroke ceramic double gate valve that often leaks in the packing position, the ceramic rotary double disc gate valve can be selected for replacement.

3.The ceramic double disc gate valve is an ideal alternative to the dome valve in piping systems.