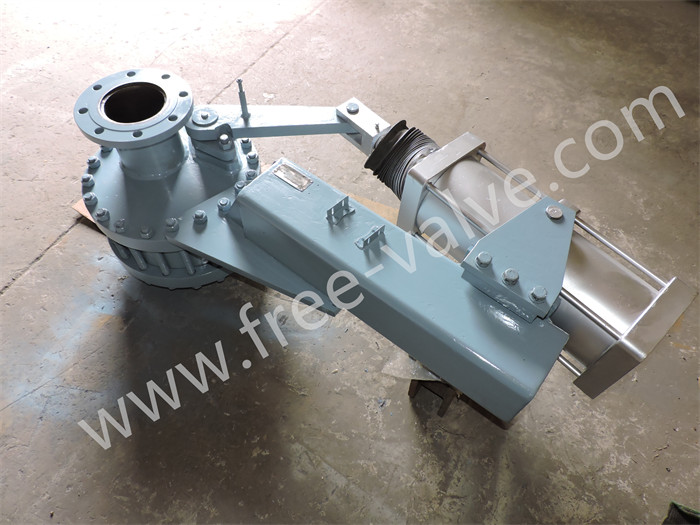

Pneumatic ceramic lined three rotating disc three-way diverter valve

FREE VALVE brand FRZ645TC pneumatic ceramic lined three-way diverter valve is widely used in fly ash, slag, cement raw material, limestone, pulverized coal, bentonite, talc, barite and other powder granular solid dry loose material conveying system.

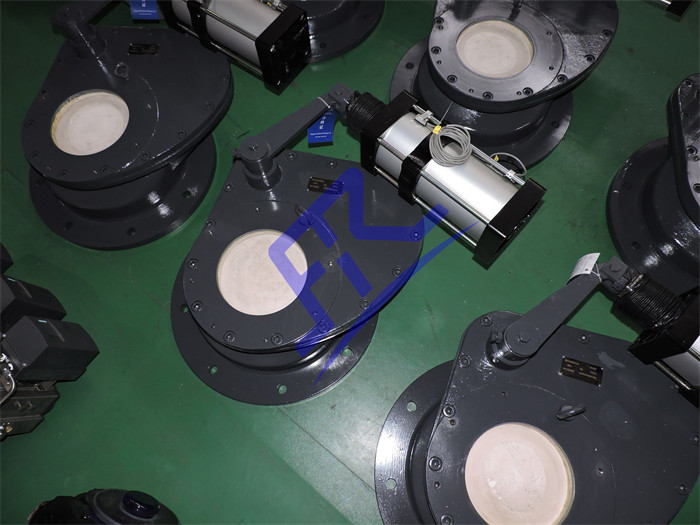

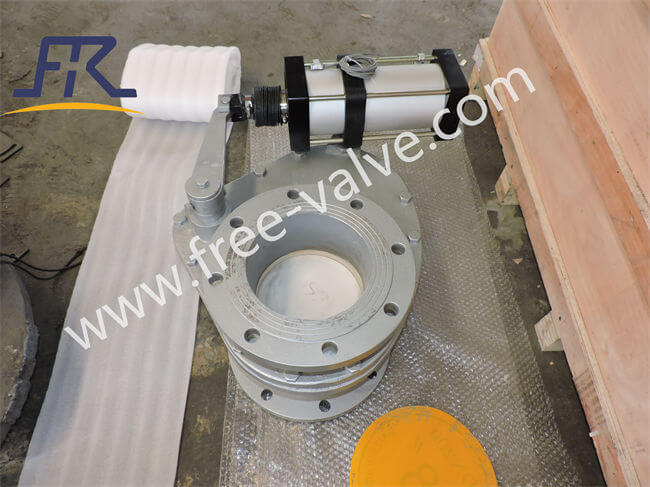

FREE VALVE brand valve body is made by cast steel parts, the sealing packing adopts wear-resistant and high-temperature fluorine rubber seals or flexible graphite composites, the sealing surface between the valve disc and the valve seat adopts wear-resistant hard alloy material or wear-resistant toughened structural ceramics, the surface is smooth, the hardness can reach 60~70HRC, which solves the problem that the sealing surface is easy to be eroded due to material erosion and the service life is not high, and the service life is 5-10 times longer than the general material valve.

The diverter valve greatly improve the safety and stability of equipment operation,so it brings good use effect and economic benefit for end users.The valve has the characteristics of good switching effect, high speed, tight sealing performance, strong wear resistance, high temperature resistance, avoid block phenomenon ,avoid jam or ash accumulation phenomenon, long service life and so on.

Features:

1.The valve is designed with one feed port and two discharge ports, the inlet and outlet angle can be arbitrarily changed.

2.The rotary shaft drives the valve disc to switch back and forth between the two discharge ports.

3.The piston rod and sealing packing of the pneumatic actuator are not in direct contact with the medium, which greatly prolongs the service life of the pneumatic actuator.At the same time, the design is a good solution to prevent valve shaft sealing material leakage.

4.The valve has a long service life, for your system safe operation provides a reliable guarantee in bulk materials handling system .

Working principle:

- The pneumatic actuator drives the valve disc through the rotating shaft and swinging arm to move back and forth between the two discharge ports to complete the switching and conveying of materials.

- The helical compression spring is loaded between the valve disc and the sealing surface, and the spring force always makes the valve disc sealing surface closely fit with the sealing ring, and allows the valve plate to move in the vertical direction, which helps to compensate the thermal expansion and cold contraction of the valve parts, and can prevent any back pressure change on the sealing effect, but also prevent the granular medium from entering between the sealing surface.

- The difference of friction force on the tangential direction of the sealing ring of the valve disc enables the valve disc to rotate during the opening and closing process, which will lead to grinding and polishing between sealing surfaces.

Technical Specification:

1) Size Range: NPS4~NPS12,DN50~DN300

2) Pressure Range: Class 150 /PN6 /PN10

3) Applicable Temperature: 0~200℃

4) Connection Type: Flange

5) Sealing material: engineering ceramics

6) Pressure test:GB/T13927, API598

7) Face to Face: GB/T12221, ASME B16.10

8) Valve body : GB/T12224,ASME B16.34

Operating Type: Pneumatic

Application:

FREE VALVE brand FRZ645TC pneumatic ceramic lined three-way diverter valve is widely used in fly ash, slag, cement raw material, limestone, pulverized coal, bentonite, talc, barite and other powder granular solid dry loose material conveying system.