What should we do for valve internal leakage

Aug 12,2021 From: Zhengzhou Free Fluid Control Technology Co.,Ltd

Valve is the control part of industrial pipeline system , which plays an important role in pipeline system. As an important component of pipeline, its sealing performance directly affects the valve use effect. However, in the field operation, the quality control of valve installation is still lacking, so that there is often valve internal leakage in the pipeline system leakage test,. Not only caused a large number of rework and economic losses, but also easy to result in the safety risks. Combined with the experiences on site , FREE-VALVE company technical team analyzes the causes of the valve internal leakage, and puts forward some feasible preventive measures, hoping to minimize the internal leakage of the valve .

1.Causes of the valve internal leakage

During pipeline installation, the main cause of internal leakage is that the valve cannot be completely closed and the sealing surface is damaged.

1.1 Lack of valve sealing and valve protection

The end of the valve is not effectively sealed during the storage and transportation of the valve, the end sealing is not completely sealed during the installation of the pipeline, and the cleanliness of the pipe is not in place, which will lead to sand, iron chips and other hard objects entering the pipeline and causing damage to the sealing surface.

The sealing surface of the valve will be damaged due to thermal deformation if the valve is thrown at will in the process of loading and unloading, or the valve cannot be closed due to mechanical deformation caused by improper protection, the valve is not opened effectively when welding the valve, and the pipe section where the valve is not treated with effective protection measures.

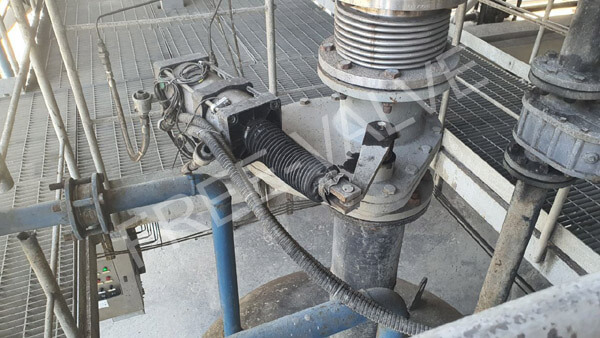

.jpg)

1.2 Valve installation quality control

Improper operation such as excessive force when the valve is operated on the hand wheel before or after installation will cause stem deformation and sealing surface damage, leading to internal leakage. In addition, in view of the large gate valves, pneumatic control valve that need to be installed vertically, if ignored the vertical degree requirements during installation, will directly affect the sealing effect, this kind of large size of the valve core weight is bigger, if installed in vertical degree is not enough, is an opening and closing, the valve wear will be more serious than under normal circumstances, so that the sealing effect to less than expected.

The valve is not opened and closed in the pipeline system purge process, and the hard sundries in the purge process under the action of high pressure purge gas will scratch the sealing surface, resulting in lax sealing and internal leakage of the valve.

2 How to avoid valve internal leakage

When handling and storing the valve, attention should be paid to the wooden or rubber plugs on both ends of the valve chamber to isolate foreign material. The valve storage site should pay attention to ventilation, so that water vapor accelerate the flow of the valve to slow down the corrosion. Do not throw the valve at will during construction to avoid the valve disc deformed as impact. In the use of valves, gate valves, globe valves, throttle valves and regulating valves should be fully closed, and ball valves and plug valves should be kept fully open.

Before installation, the impurities in the pipe section where the valve is located should be thoroughly cleaned. The impurities in the pipe can be poured out by tilting the pipe and tapping the pipe with a soft object when lifting the pipe, or clean compressed air can be used to purge. When installing the welding valve, the valve should be opened before welding, and the welding method of argon arc welding is used to make the base work, so as to minimize the thermal deformation of the valve body and avoid the welding slag accidentally falling into the valve during the welding process. When the installation of the flange valve requires high verticality , the pipe flange should be installed in the middle of the span before installing the valve to ensure its verticality. For the whole heat treatment of the pipeline, the pipeline should be heat treated before installation , and then do local heat treatment, so as to minimize the thermal deformation. When operating and checking the valve, do not operate too much force to damage the stem and sealing surface. In addition, when the pipeline pressure test and cleaning and purging, special attention should also be paid to the control of the valve opening degree, to avoid high-pressure fluid with impurities impact sealing face and sealing face damage.

In a word , valve leakage mainly for the valve fails to completely locked and sealing surface is damaged.The main reason is the operation people quality consciousness is not strong, not strictly carry out the whole process of the finished product protection valve, lead to deformation of the body parts, cannot be fully closed, the second reason is not strictly enforce the valve installation process, The sealing surface is damaged and the sealing performance is affected. In view of the causes of valve internal leakage, the corresponding preventive measures are put forward to reduce the occurrence of valve internal leakage, so as to promote the improvement of the whole pipeline installation quality.

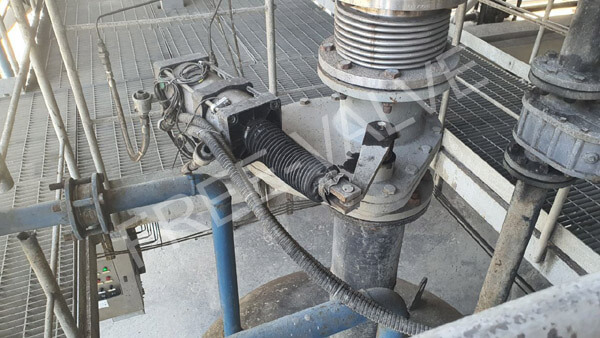

.jpg)