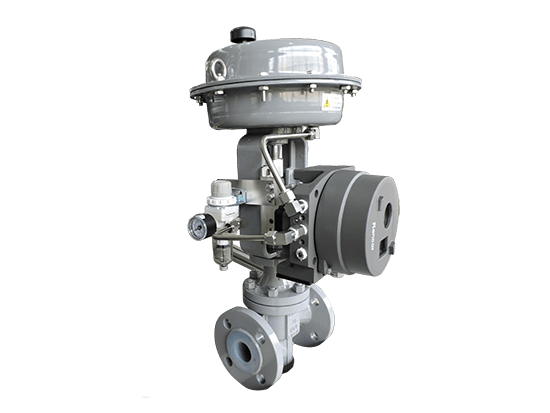

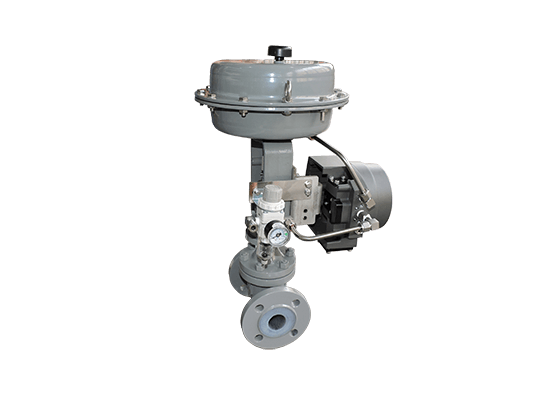

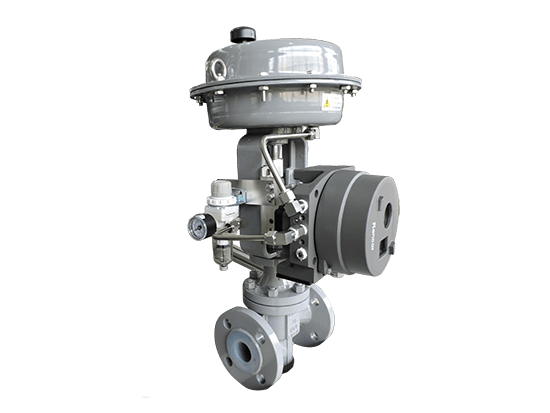

FREE-VALVE pneumatic fluorine lined globe control valves are designed for process industry and equipment requiring high adjustment accuracy and small leakage, and to control the flow of highly corrosive or aggressive fluids within industrial processes. It adopts integral rubber encapsulation technology, and the valve body cavity, valve bonnet, valve disc and other parts (i.e., chemical medium overflow parts) in contact with the medium are all made of excellent corrosion-resistant materials as lining or coating materials, and the valve adopts molded lining molding technology, so that the valve has both metal strength and corrosion-resistant characteristics.

1.The valve disc and valve stem are designed as one piece part, which can prevent the possibility of the inner parts being flushed out of the valve body caused by the pressure fluctuation of the pipeline.The structure is compact and the use is safe.

2.The valve achieves equal percentage or linear flow characteristics through the dynamic relationship between the valve disc profile and the flow area of seat.

3.The lining material is optional, which can be applied to a variety of media ,the valve has good corrosion resistance.All internal parts are coated with anti-corrosive material.

4.The valves have three structural forms : Direct flow, oblique type, and angle type, among which direct flow type is the most commonly used. Angle type can be installed at the corners of pipeline systems,this structure saves 90° bends and is easy to operate, and oblique type resistance is the smallest among globe valves,the stem of this type of valve is at an Angle to the channel.

5.Fluorine lined globe control valve adopts precise and small pneumatic and electric actuators, small in size and light in weigh.

FREE-VALVE pneumatic fluorine lined globe control valves provide precision control performance, tight shut-off capabilities and high reliability in a wide range of applications, adopts integral rubber encapsulation technology, which has excellent anti-corrosive performance and is suitable for a variety of strong corrosion conditions, and is widely used to handle extremely corrosive substances such as sulfuric acid, salt sulfur, and alkali. Therefore, These pneumatic fluorine lined globe control valves are essential for industries dealing with chemical processing,oil refining,medicine and other similar fields where the handling of aggressive media is necessary.

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible.( * is required information)

.png)